.png)

パッケージ

輸送中もワイヤーの品質を保持するために、Fort Wayne Metalsは様々なパッケージオプションを用意しています。 様々なオプションからお好みのスプールタイプを指定できます。または弊社がお客様固有のニーズに最適と思われるスプールタイプをお勧めします。

一部の合金素材は錆びやすい為 通常の袋詰めに乾燥剤を入れて防錆効果を高めております。

直線加工された製品やカット品は数量に応じPVCチューブ もしくは木製クレート梱包にして出荷されます。

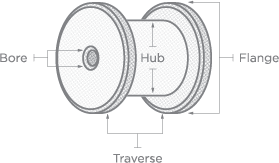

| スプール | 同等品 | フランジ | ハブ | 幅 | ボア | 最大容量* | 直径 | スプール組成 |

|---|---|---|---|---|---|---|---|---|

|

55.88 cm x 27.94 cm |

-- |

55.88 cm |

35.56 cm |

27.94 cm |

12.7 cm |

204.1 kg |

0.762 mm ~ 3.66 mm |

ポリスチレン |

|

45.72 cm x 25.4 cm |

-- |

45.72 cm |

27.94 cm |

24.38 cm |

12.7 cm |

68.03 kg |

0.762 mm ~ 3.66 mm |

ポリスチレン |

|

30.48 cm x 15.24 cm |

-- |

30.48 cm |

15.24 cm |

15.24 cm |

3.3 cm |

27.21 kg |

0.304 mm ~ 1.524 mm |

ABS |

|

溶接ワイヤー |

-- |

29.72 cm |

21.08 cm |

9.2 cm |

5.08 cm |

13.60 kg |

0.102 mm ~ 1.27 mm |

ABS |

|

20.32 cm x 8.89 cm |

-- |

20.32 cm |

11.68 cm |

15.24 cm |

3.048 cm |

11.33 kg |

0.304 mm ~ 1.524 mm |

ABS |

|

15.24 cm x 8.89 cm |

-- |

15.24 cm |

8.89 cm |

8.89 cm |

1.575 cm |

4.54 kg |

0.076 mm ~ 0.508 mm |

ABS |

|

34.59 cm x 9.017 cm |

-- |

34.59 cm |

28.34 cm |

9.017 cm |

5.08 cm |

6.803 kg |

0.0508 mm ~ 0.762 mm |

ABS |

|

11.43 cm x 7.62 cm |

-- |

11.43 cm |

6.35 cm |

7.62 cm |

1.57 cm |

1.133 kg |

0.076 mm ~ 0.254 mm |

ABS |

|

6.35 cm x 7.62 cm |

HK 76-45 |

6.35 cm |

4.318 cm |

7.62 cm |

1.57 cm |

0.453 kg |

≤0.177 mm |

ABS |

|

HK 76-45 |

6.35 cm x 7.62 cm |

6.35 cm |

4.445 cm |

5.994 cm |

1.57 cm |

0.453 kg |

≤0.101 mm |

-- |

|

DIN80 |

-- |

8.128 cm |

5.08 cm |

6.35 cm |

1.60 cm |

0.453 kg |

≤0.0762 mm |

ABS |

|

DIN100 |

-- |

9.606 cm |

6.35 cm |

7.874 cm |

1.60 cm |

1.360 kg |

0.0254 mm ~ 0.127 mm |

ABS |

|

DIN125 |

HKV 125 |

12.446 cm |

7.874 cm |

9.906 cm |

1.60 cm |

2.267 kg |

0.101 mm ~ 0.254 mm |

ABS |

|

HKV 125 |

DIN125 |

12.496 cm |

7.112 cm |

6.502 cm |

1.60 cm |

1.360 kg |

0.101 mm ~ 0.254 mm |

-- |

|

DIN160 |

HKV 160 |

16.002 cm |

9.906 cm |

12.7 cm |

2.209 cm |

4.54 kg |

0.254 mm ~ 0.508 mm |

ABS |

|

HKV 160 |

DIN160 |

16.002 cm |

8.99 cm |

8.509 cm |

2.209 cm |

4.54 kg |

0.254 mm ~ 0.508 mm |

-- |

|

DIN250 |

-- |

24.892 cm |

16.002 cm |

16.002 cm |

2.209 cm |

9.071 kg |

0.304 mm ~ 1.016 mm |

ABS |

|

Wardwellボビン |

-- |

6.604 cm |

3.302 cm |

7.112 cm |

2.794 cm |

0.226 kg |

≤0.0762 mm |

ナイロン |

|

中型 ブレードボビン** |

-- |

4.267 cm |

2.578 cm |

2.641 cm |

1.054 cm |

0.113 kg |

≤0.0762 mm |

アセタール コポリマー |

|

大型 ブレードボビン** |

-- |

3.987 cm |

2.971 cm |

2.641 cm |

1.054 cm |

0.054 kg |

≤0.0762 mm |

アセタール コポリマー |

|

New England #2 |

-- |

4.318 cm |

1.574 cm |

6.35 cm |

0.762 cm |

0.340 kg |

≤0.127 mm |

ナイロン |

|

Endura® ボビン** |

-- |

4.292 cm |

2.590 cm |

3.556 cm |

1.054 cm |

0.090 kg |

≤0.0762 mm |

アセタール コポリマー |

|

*実際の容量はワイヤー径と合金タイプによって異なります。 詳細は、カスタマーサービス担当までお問い合わせください。. |

||||||||

Endura® ボビン

Endura® ボビンのアングルフランジのデザインは、スプール中のワイヤー重なりを避け、ペイオフ中にワイヤーがフランジに接触することを最小限に抑え、フランジがトーインする可能性を排除します。 各スプールはたるみのない滑らかな表面を実現するよう慎重に生産されます。 多くのEndura® ボビンが従来の同等品をシンプルに置き換えたデザインであるため、切り替えはいたって迅速、簡単です。 機械の稼働時間を改善することでお客様の製造プロセスが利益を生み出す可能性がある場合、Fort Wayne Metals代理店にご連絡ください。Endura® ボビンでそれを達成する方法をご紹介いたします。

ラベル

弊社のパッケージング工程で最も重要な部分は、スプールラベリングを通じた品質管理です。通常、スプールラベルに記載される情報:

- 合金タイプ

- サイズ

- ロット番号

- スプール正味重量

- 顧客発注番号

- 日付

- スプール番号

- 極限引張強さ

- 平均破壊荷重

- ワイヤーの伸び率

スプール返品およびリサイクル

環境フットプリントを削減する取り組みとして、Fort Wayne Metalsは弊社のスプールを良好な状態で返却したお客様に預り金の50%を返金しております。 (送料はお客様のご負担になります。)

この返金を受ける場合、スプールは以下の条件を満たした時に「良好な状態」とみなされます:

- ワイヤースクラップやその他の材料破片がない。

- 新しい穴を開けるなどの加工を行っていない。

- 通常の合理的な摩耗以上の損傷がない。

スプール預り金は、Endura®ボビン、破損したスプール、および一部のサイズや使用目的のスプールについては返金されませんが、Fort Wayne Metalsは持続可能性イニチアチブの一環としてそれらの返却を受入れます。 リサイクル可能な製品が埋立地に送られる量を減らすために、メーカー、およびその他の環境責任を負うベンダーを通して様々なスプール組成物をリサイクルします。

使用済みのスプールは直接Fort Wayne Metalsリサイクルセンターへお送りください。 そうすることで、製品輸送に関する環境への影響度を最小限に抑えることができます。

Fort Wayne Metals - Building D

4030 Piper Drive

Fort Wayne, Indiana 46809

All spool returns must include a packing slip detailing the spool type, quantity, and color for all spools included in the return.

Fort Wayne Metals encourages our customers to take advantage of the spool return program. Please reach out directly to your Customer Service Assistant if you have any questions about the spool return program or recycling options. To find out more about Fort Wayne Metals Recycling Program and Sustainability Initiatives, please visit the Corporate Responsibility page.